Supply chain disruption is not a problem isolated to a few unlucky companies - every business that uses a supply chain will experience a disruption at some point. It may be small enough to work around easily, but it can also be large enough to bring the normal momentum of business to a screeching halt.

Consider this: in the home, even if we experience blackouts very occasionally, we still breathe a sigh of relief when we know the exact drawer to head to for a flashlight or candles.

Having a solid disruption plan is like having a well-stocked emergency drawer - instead of a flashlight, however, your saving grace will be a backup plan and a wide supply chain network that can bend without breaking.

Are Supply Chain Disruptions Serious?

If you have a problem connecting to your intended sales audience, you have almost limitless options for correcting the situation. You can adjust your marketing, your future ordering levels, your 3PL provider(s), or even your price points because each of those facets is handled internally.

If your supply chain suffers from a connectivity problem, however, fixing the issue becomes more complex, multiplied in difficulty by every trading partner the problem passes through. That means a disruption is less of a "hiccup" and more of an avalanche that could threaten your company well before it reaches your warehouse.

No matter how niche your industry, or how stable your supply chain, it's highly unlikely you're completely safe from a supply chain disruption. Your trading partners need to source components and raw materials, after all - even their packaging is a potential pain point when looking "up-chain." A single "act-of-God-level" weather event can wipe a producer's facility completely off the map, leaving unprepared companies with a huge, sudden gap in their supply chain.

If you don't want to end up a member of that hapless group, you'll need to take steps now to safeguard your interests in the event of a disruptive event.

What Constitutes a Supply Chain Disruption?

Disruptions can be internal or external, avoidable or inevitable — the unpredictable nature is one of the most important reasons to prepare for them.

Transportation is one of the most recognizable disruption sources, as shown in sweeping impacts like 2015's West Coast port closure, or the devastating sole bridge break between Eastern Canada and Western Canada a scant year ago. These breakdowns - of both the literal and figurative variety - can throw a huge wrench in your 3PL planning.

Even smaller slowdowns - tornadoes in the Midwest, or snowstorms in the north - can delay your supply chain by days or even weeks, leaving you without the products or conveyance you need to stay on schedule. Any instance where a vehicle or vessel needs to move products from point A to point B is a place where a disruption could strike.

Human error is another, often overlooked culprit of disruptive events. As warehouses and manufacturing facilities rely more and more on computerized systems, it's crucial that human input is as flawless as possible - unfortunately, that's not the nature of human interaction. A single tired employee hitting the wrong button can result in you getting hundreds of units of the wrong product - or not getting your shipment at all.

When the source of the error explains they need time to fix the issue, preparation is the difference between needing to wait patiently on their time table or moving ahead on your own.

Storage concerns are another red flag that shouldn't be overlooked. If your product(s) requires special handling, such as refrigeration ranges for vaccines, mishandling or poor temperature documentation can turn an entire delivery unviable in an instant. For issues like temperature, the "fix it" clock starts ticking immediately when a problem is discovered.

Would you rather start finding a solution from scratch when time is of the essence, or lean on your alternate-resource playbook and keep the endangered batch viable for sale and distribution?

Business planning doesn't get much attention as a potentially disruptive event, but a bad business forecast can derail your supply chain as quickly as an actual train derailment. Studying your sales data and ensuring your forecasts are hitting the historical mark is as much a part of warding off supply chain disruption as lining up a backup logistics provider.

The Stages of Disruption

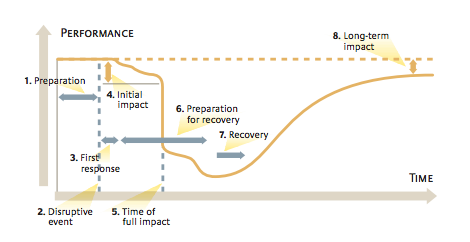

Supply chain disruptions cannot be thought of in a simple cause-and-effect framework if you want to successfully overcome them. Learn to recognize and structure your company to weather these eight stages of a disruptive event (provided by our friends at MIT):

- Preparation - Contingency plans should be discussed with fair regularity, and on-demand if a potential predictive disruption - e.g. a transportation labor strike - looks likely. Committing to a proactive stance, rather than a reactive one will give you additional lead time that could push you ahead of competitor's results in later stages.

- The Disruptive Event - The worst actually happens. The weather event shuts down your supply lines, the company you depend on can't fill orders, or another obstacle brings your chain productivity to a screeching halt.

- First Response - The first moves you make post-event are the most crucial. If you panic and over-react, you'll be paying the price of that exaggeration well after the danger recedes.

- Initial Impact - This is when the results of the disruptive event become plainly obvious. Competitors are scrambling for the same alternate supply lines or services that you are, a frenzy that highlights how important your first response truly is.

- Full Impact - After the dust settles, you'll be able to get a true picture of the issue's scope. This is the right time to critically re-assess your plans going forward.

- Recovery Preparation - This is where you'll talk to your supply chain trading partners and discuss how you'll collectively overcome the situation at hand.

- Recovery - Implementation of your collaborative plan starts, and slowly the immediate negative effects of the disruptive event start to ebb.

- Long-Term Impact - Just because an event ends doesn't mean its impact does as well. Brace for hidden costs and expenses as your recovery naturally progresses.

Am I Safe From a Disruption?

A vulnerability assessment should always be considered an integral part of your SWOT analysis.

Thankfully, it's a fairly straightforward process that involves three key questions:

- What can go wrong?

- What is the likelihood of that happening?

- What are the consequences if it does happen?

You'll need to carefully weigh likelihood against the cost - both financial and effort-wise - of preparing for a potential disruption scenario. Every industry will have different concerns and risk profiles, so make sure you're addressing the most common scenarios for your business.

Best Practices for Avoiding Disruptions

Build both redundancies - keeping more than one supplier or service provider on call - and flexibility into every aspect of your supply chain that can accommodate them.

The more transparent and prone to data-sharing a trading partner is, the stronger their "link" in your supply chain. Form your partnerships intelligently to leverage the inherent strength of trading partners as they contribute to your supply chain.

In the same vein, when selecting a 3PL to work with, always look for multi-client service offerings. These will help you distribute costs like overhead, labor, and warehousing by sharing them with peers - driving your financial liability in a disruption down substantially.

The cost savings of this approach also means it's more affordable to warehouse safety stock, keeping you better prepared in a shortage of finished products or manufacturing components.

Intelligent Supply Chain Flexibility

Learning from past mistakes - either your own or an industry peer's missteps - is a great starting point for your disruptive event preparations.

Kenco, for example, works with a client that experienced a significant disruption in their supply chain when Hurricane Katrina hit New Orleans. Now, some of their overflow products are safely stored in a Tennessee facility under Kenco's care, and external factors like broken levees are no longer able to wash away the efforts of that business.

Almost every industry has a similar "learned my lesson" story about adjusting supply chain behaviors after a disruptive event.

In the automotive industry, for example, Takata was infamously found to be turning out faulty airbags to several automotive manufacturers. Faced with their sole source of product cut off out of necessity, the company now utilizes 2-3 external manufacturers to produce. That way, if a similar problem arises in the future, they're able to simply shift to their secondary supplier(s) and continue production uninterrupted.

To Sum It All Up

Realistically, attractive attributes like redundancy and flexibility do come with up-front costs, but the expense of not having them in a disruptive crisis is far higher.

Shore up your own disruption defenses and look to form beneficial partnerships with companies like 3PL providers with experience in multi-client services.

If you're interested in learning more about our services and experience with multi-client services, check out our eBook, Uncommon Value: Customized Logistics Solutions and Optimizing 3PL Relationships.

Remember, you will need a contingency plan for a disruption at some point in your operation, and as the saying goes, an ounce of prevention is worth a pound of cure.