Supply chain network design is a crucial part of any supplier's business strategy. The distribution centers, delivery routes, time taken in between deliveries, and end destination are all steps that have to be monitored and tweaked at every chance to ensure an optimized network.

Understanding this network can be the difference between saving tens of thousands of dollars or expending it--especially if you deal in multiple regions across thousands of miles.

But finding the one issue that's holding back your supply chain network isn't easy. It can seem overwhelming or too complex to navigate at first. However, there are some key metrics to help you see how your supply chain is performing at a glance.

If you're curious to see if your supply chain is performing, here are 5 signs that may mean your supply chain network design is poorly optimized:

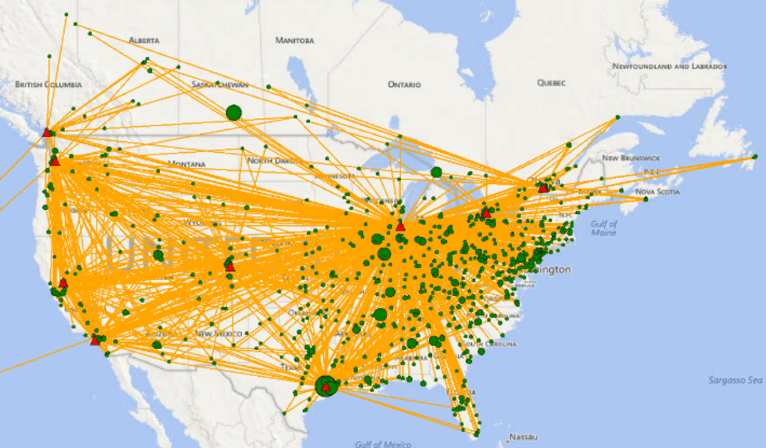

1. The Spider Web Map

For every client, we establish a baseline using a map of the U.S. We plot the company's shipping information from the past 12 months, and we recreate the routes on a map, with point-to-point lines between the distribution center and the customer. Most of the time, the map looks like a spider web--every line is intersecting.

For example:

You don't have to be an expert in logistics to see this map is a little rough. If your map looks like a spider web, or worse; there's room for optimization. It could result from inventory levels driving the use of backup distribution centers or a lack of distribution centers. Either way, it's easy to see that there's an issue.

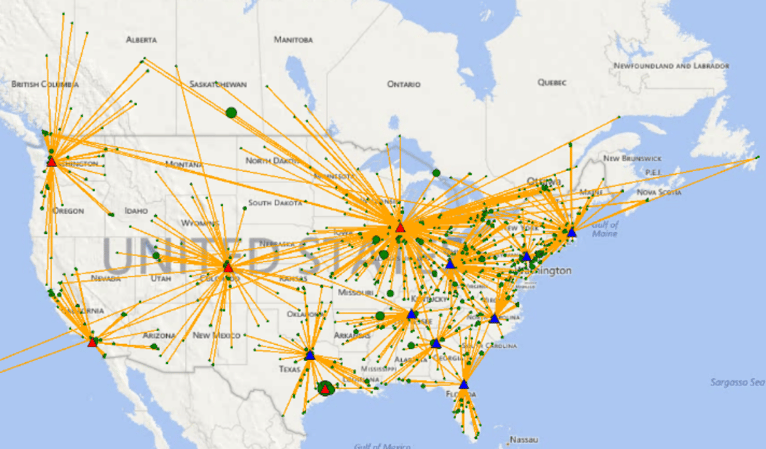

In an optimized network, you'll see more of a cluster diagram, with routes shooting out from different cities. An optimized network is very centralized around distribution centers. Southeastern customers are serviced from Atlanta, Western customers from California, etc.

For example:

2. A High MPD

MPD (miles per delivery) is a fairly common metric in the logistics industry. When benchmarking your MPD, there are certain numbers you'll want to be hitting.

You'll typically want your MPD between 150 and 300. Sitting below 1,000 is still generally good, but if you're anywhere in the 550 - 1,000 range, that's an issue. You're basically moving halfway across the country to make deliveries.

If your MPD is out of hand, it will have an overarching effect that distorts other metrics. Your MPD will be the easiest way to see if there's a general optimization problem with your supply chain.

3. Low Percentage Or High Delivery Day Radius

The percentage of deliveries you can ensure within a one-day radius is another key metric you should be watching. The optimal numbers you should be shooting for is a 95% 2- or 3-day delivery. Any smaller percentage or longer day delivery is an issue.

A typical driver can do 550 miles each day. So a 1-day delivery radius is around 550 miles, give or take. With every delivery you want to hit every below or at 1,000 miles, making it a 2-day delivery.

If you're missing this metric, it could be from a lack of distribution centers, or incorrectly assigned distribution centers in certain regions.

4. Fuel Cost Per Trip

Watching your fuel cost is a key component to any optimized supply chain.

When calculating your fuel cost per trip, look at your fuel cost as a percentage of the total cost of the trip as part of your benchmark. Though we don't have an optimal fuel cost per trip, you should push for 7.7 to 8.2 MPG with drivers. If you're outside of this range, your fuel cost could be an issue.

5. Frequent Use Of Backup Distribution Channels

Outside of other problems, poorly managed inventory can cause supply chain design issues. If you run out of inventory, then you have to fall back on your backup distribution center. And if this happens often, it will severely damage your percentage and delivery day radius.

Ask yourself, "Do I have the proper safety stock levels to hit my service level needs?" If you can't confidently answer, "Yes," you need to work on the internal management of your inventory.

To Sum It All Up

Your supply chain network design is a complex system that's constantly evolving, but if you've seen any of these signs, there's still room for improvement. Whether it's taking the time to comb through your supply chain or partnering with a 3PL, looking into these signs and making changes can help your company.