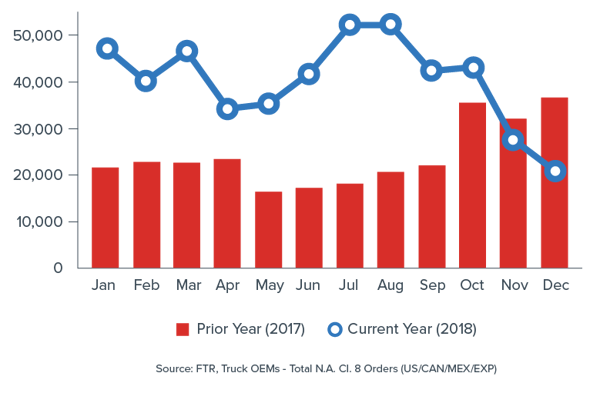

For the majority of 2018, the load-to-truck ratio, which measures how many loads are available per truck, was high. In fact, some markets experienced peaks of eight to ten loads per truck in the second quarter of 2018. Given that the main index for capacity was trending downward, fleets started to order more trucks as a result, increasing rates and adding capacity in the market. In 2018, Class 8 New Truck Orders broke a 14-year record with 490,100 units ordered compared to the previous record in 2004 of 390,000.

Ahead of 2019, reports indicated that shippers and private fleets would face continued capacity pressure for the next 18 months. However, in the fourth quarter of 2018, the market instead began to soften. Talks of a recession resulted in declining consumer confidence, and a slower than expected holiday season had a particularly significant effect on the retail industry.

A softer market greatly impacts carriers and shippers with private fleets as they are left to deal with the financial fall out of the decreased equipment utilization. Operating a fleet that is under-utilized causes shippers’ costs to skyrocket. So, how can shippers improve their situation in this volatile market? Below are three areas worth examining:

Consider dedicated fleet management

When the freight market increases, shippers should look for more dedicated, committed capacity. This involves partnering with an outsourcer to deploy a private fleet for a part of the organization’s network. Dedicated capacity insulates shippers from the rate swings in the market, while providing the highest level of service available. This mode removes the shipper from the freight market completely by transitioning them to a cost model based on operating costs and efficiencies, not supply and demand.

Implement indexing technology

As the industry has evolved, 3PLs have become a strategic technology partner for shippers rather than a tactical execution vendor. Offering real-time tracking, automation from an execution and planning standpoint, and incorporating live market indexes allow 3PLs to buy freight at the market price every time.

Knowledge-based procurement has replaced volume-based procurement, and 3PLs leverage their investment and mastery of powerful tools across many customers to create a cost-effective solution, which would not make economic sense for most individual shippers to re-create on their own. Speed to value is low and costs are very high for discrete shippers looking to implement these technologies. However, 3PLs have enterprise licenses, shared professionals, spanning system super users, IT infrastructure, procurement tools, and engineering insight, allowing them to offer the technology for much less by distributing the investment among multiple tenants.

Knowledge-based procurement has replaced volume-based procurement, and 3PLs leverage their investment and mastery of powerful tools across many customers to create a cost-effective solution, which would not make economic sense for most individual shippers to re-create on their own. Speed to value is low and costs are very high for discrete shippers looking to implement these technologies. However, 3PLs have enterprise licenses, shared professionals, spanning system super users, IT infrastructure, procurement tools, and engineering insight, allowing them to offer the technology for much less by distributing the investment among multiple tenants.

Leverage a comprehensive approach

Within most 3PLs, there is a brokerage group, an asset base group, and a transportation management team, allowing them to look across business lines and analyze data holistically. Whether it is looking at capacity data from a brokerage customer, freight data from a transportation management customer, or data from a customer that is dedicated to moving trucks, a wide-ranging view allows 3PLs to see how information from multiple sources can be integrated to deliver better insights.

This approach brings greater predictability and more stability into the supply chain. By using data from multiple shippers, one shipper can benefit from information from another organization that may be moving in an opposite direction. It also provides a line of sight into all the activity moving within your organization to drive continuous improvement activities.

To manage fluctuating capacity and avoid volatile market projections, it is important to work with a company that utilizes a strategy that best aligns with your organization’s supply chain goals. It is critical to collaborate with a partner that has your interests in mind and offers full transparency throughout the process. Find a partner whose core competency is monitoring the market. These organizations have a more complete understanding of the market and can pull levers to keep you ahead of the curve – and your competitors.